The complement {industry} is witnessing its most important protein innovation since whey isolate revolutionized post-workout diet a long time in the past. However this time, the breakthrough comes from actually skinny air.

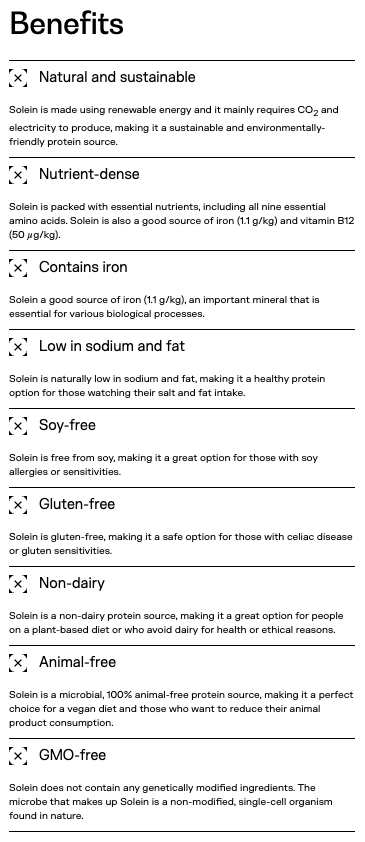

Finnish firm Photo voltaic Meals simply made protein powder from literal air! Solein® makes use of microbes that eat hydrogen + CO2 to provide 78% protein with all important amino acids. It’s additionally already GRAS self-affirmed and in manufacturing.

Meet Solein®, a protein powder that basically challenges every part we thought we knew about how protein will get made. Whereas the {industry} has spent years debating plant versus animal sources, optimizing absorption charges, and perfecting taste profiles, Finnish firm Photo voltaic Meals quietly solved a a lot greater drawback: they discovered create full protein without having farms, animals, and even crops.

Out of Skinny Air: A Sustainable Protein Supply Not like Any Different

Solein® represents the primary commercially viable protein utterly disconnected from agriculture. As a substitute of counting on crops that want months to develop, climate that should cooperate, or animals that require huge sources, Photo voltaic Meals makes use of hydrogen-oxidizing microbes that actually eats air molecules to provide protein in simply 70 hours.

The expertise seems like science fiction, however the outcomes are remarkably sensible. Photo voltaic Meals has been producing Solein® at their Manufacturing facility 01 facility in Finland since 2024, with regulatory approval already secured in Singapore and GRAS standing obtained in the US. This isn’t a laboratory curiosity or a distant future chance — it’s occurring proper now.

Solein® is revolutionary for a number of causes that transcend its distinctive manufacturing technique. The environmental implications are monumental: this course of makes use of 95% much less land than conventional animal proteins and may be 20 occasions extra environment friendly than plant-based options. Extra importantly for our {industry}, it opens up completely new prospects for sustainable protein sourcing that might reshape how we take into consideration diet and supplementation.

A Fermented Protein Supply that Bests Plant-Based mostly Protein’s Amino Profiles… and it’s non-GMO!

However right here’s what actually issues: Solein® delivers a full amino acid profile in a neutral-tasting powder that may seamlessly combine into present formulations. Photo voltaic Meals isn’t asking customers to sacrifice high quality or style for sustainability — they’re providing a genuinely superior resolution that occurs to unravel a few of humanity’s largest environmental challenges alongside the best way.

The age of meals and protein “out of skinny air” has formally begun, and the implications prolong far past simply one other ingredient possibility. This might be the expertise that lastly permits world protein manufacturing to scale with out the environmental prices which have plagued conventional sources. It’s even on the drafting board for use as a meals supply for astronauts in outer area!

Able to discover how non-GMO historical microbes, electrical energy, and a few very intelligent Finnish engineering would possibly remodel your subsequent protein shake? Let’s dive into the science, the sustainability, and the longer term implications of what could be a very powerful protein innovation of our lifetime. However earlier than we do, join our Photo voltaic Meals and Solein® information alerts — you’re not going to wish to miss what this firm has coming.

Subscribe to PricePlow’s E-newsletter and Alerts on These Subjects

What’s Solein®? The Science Behind Protein “Out of Skinny Air”

To grasp why Solein® is such a revolutionary leap ahead, we have to study the outstanding biology that makes it potential. Whereas the “out of skinny air” tagline captures the creativeness, the fact includes a complicated microorganism that has been perfecting this course of for hundreds of thousands of years.

The Organic Basis

Single-cell organisms: At its core, Solein® consists of dried hydrogen-oxidizing microbes (HOB) — particularly, single-celled organisms that belong to a gaggle of autotrophic microbes able to creating their very own meals from inorganic compounds.[1] Photo voltaic Meals makes use of a selected pressure from the Xanthobacter genus — naturally occurring hydrogen-oxidizing microbes found in Finland’s wealthy biodiversity. This non-GMO microbe is understood for environment friendly protein synthesis, making it an ideal locally-sourced selection for a hydrogen-oxidizing organism for industrial protein manufacturing.

Solein® is Made From Non-GMO Microbes!

These aren’t genetically modified organisms — they’re naturally occurring microbes that Photo voltaic Meals found in Finland’s atmosphere. As Susanna Mäkinen, Head of Biology at Photo voltaic Meals, explains: “The microbe on the coronary heart of Solein®’s story was plucked from the wealthy biodiversity of Finland’s nature. Little did it know that it might be the ancestor of trillions of comparable yellow cells.”

Chemosynthesis course of: Not like crops that depend on photosynthesis to transform daylight into power, Solein®’s microbes use a course of known as chemosynthesis. On this outstanding organic pathway, the microbes oxidize hydrogen gasoline, primarily eradicating electrons from hydrogen molecules, which releases power.[2]

This power powers the microbes’ potential to repair carbon dioxide from the air, remodeling it into natural compounds together with full proteins. The method requires no daylight, making it unbiased of climate situations and able to working 24/7 in managed environments. This organic equipment permits the microbes to realize CO2 discount efficiencies that truly exceed pure photosynthesis.[2]

Fermentation vs. conventional yeast: The important thing distinction between Solein® and conventional fermented proteins lies of their feedstock necessities. Typical yeast fermentation, whether or not for brewing, baking, or protein manufacturing, depends on sugar as its main carbon and power supply. This sugar usually comes from crops like corn, wheat, or sugar cane, making a dependency on agricultural land and sources.[3]

Solein®’s microbes get rid of this sugar dependency completely. As a substitute, they eat gases which might be ample in our environment: carbon dioxide, hydrogen (produced by way of water electrolysis utilizing sustainable electrical energy), and oxygen. This basic distinction means Solein® manufacturing is utterly unbiased of crop agriculture: It doesn’t compete for agricultural land, doesn’t require particular climate situations, and doesn’t rely upon harvest seasons.[4]

The fermentation course of itself happens in fastidiously managed bioreactors the place temperature, pH, and gasoline concentrations are exactly managed. This managed atmosphere permits for constant, predictable manufacturing whereas eliminating contamination dangers that may plague agricultural programs.

Biomass Fermentation vs. Precision Fermentation: A Important Distinction

It’s necessary to grasp that Solein® makes use of biomass fermentation, not precision fermentation. This distinction basically modifications each the method and the tip product. In biomass fermentation, the microbes themselves grow to be a part of the ingredient after pasteurization and drying, just like how yeast turns into a part of bread, beer, cheese, and yogurt throughout conventional fermentation processes. All the microbial biomass is harvested as the ultimate protein product, with no separation required.

Precision fermentation, utilized by firms like Good Day, operates otherwise: there, microbes (whether or not they’re yeast, fungus strains, or micro organism) are genetically-modified utilizing CRISPR and are fed substrates to provide particular proteins or compounds which might be then separated from the microbial biomass. Solein® is not that! Such a course of requires intensive downstream processing to isolate the specified product whereas the microbial biomass typically turns into waste.

Solein®’s method eliminates this complexity – the microbes are a part of the product, making it a extra environment friendly and waste-free course of that mirrors humanity’s oldest fermentation traditions.

Manufacturing Course of Breakdown

The transformation from air molecules to protein powder includes 4 exactly orchestrated steps that happen in Photo voltaic Meals’ Manufacturing facility 01. This isn’t theoretical manufacturing – it’s a confirmed industrial course of producing protein day by day.

The distinctive golden colour comes from Photo voltaic Meals’ Xanthobacter microbes — the identical non-GMO organisms that convert hydrogen and CO2 into nutritious protein. Lab technicians usually pattern the protein powder to make sure constant high quality and that attribute creamy texture with refined umami notes.

-

Water electrolysis

The method begins with renewable electrical energy splitting water (H2O) into its part gases: hydrogen and oxygen. This electrolysis step is the energy-intensive basis of your entire system, requiring roughly 18-30 kWh per kilogram of ultimate biomass produced.[5] Photo voltaic Meals emphasizes utilizing renewable electrical energy for this step, making your entire course of carbon-neutral when powered by clear power sources.

The electrolysis happens in specialised items designed for top effectivity, with alkaline electrolysis expertise attaining industry-leading system efficiencies. The hydrogen and oxygen produced are then fed instantly into the fermentation system, eliminating the necessity for gasoline storage and transportation.

-

Gasoline fermentation

Inside steady stirred-tank bioreactors with volumes reaching 200 m3, the hydrogen-oxidizing microbes eat their fastidiously balanced gasoline eating regimen. The standard gasoline ratio is CO2:O2:H2 at 1:2:7 volumetric proportions, creating optimum situations for microbial protein synthesis.[5]

The microbes additionally obtain a water-based mineral medium containing important vitamins: ammonium as a nitrogen supply, plus inorganic salts with sulfur, phosphorus, magnesium, sodium, potassium, iron, and calcium. Hint parts together with manganese, zinc, molybdenum, cobalt, nickel, and copper are added in minor quantities.[1]

Temperature, pH, and gasoline concentrations are exactly managed all through the fermentation, with phosphoric acid and sodium hydroxide used to take care of optimum pH ranges. This managed atmosphere permits the microbes to realize hydrogen conversion efficiencies that transcend 90%, which bests earlier analysis from even a decade in the past.[5]

-

Harvesting

The protein fortifies pasta with full amino acids whereas sustaining the genuine taste profile customers anticipate — no masking brokers or taste programs wanted.

Right here’s the place Solein®’s velocity benefit makes the method into a real scientific marvel: The continual cultivation course of means contemporary protein is prepared for harvest each 70 hours in an uninterrupted cycle that by no means stops producing! To place this in perspective, spring wheat requires 100-130 days to develop, winter wheat wants 180-250 days, and egg-laying hens don’t even start producing protein till they’re 5 months previous.

Each Day is a Harvest Day

This speedy turnaround means Manufacturing facility 01 operates on what Photo voltaic Meals calls “day-after-day is a harvest day” — steady manufacturing regardless of seasons, climate, or agricultural cycles. The bioreactor produces the identical day by day protein output as 300 dairy cows, however with out the environmental affect or useful resource necessities.

-

Processing

After cultivation, the microbial broth undergoes warmth remedy, focus and drying.[1] First, the broth is pasteurized by heating with recovered warmth, guaranteeing meals security whereas sustaining dietary integrity. The pasteurized broth then proceeds to separation, the place steady centrifugal separation removes the liquid supernatant (the liquid portion separated from the cells) from the concentrated microbial biomass. The supernatant is shipped to wastewater remedy, whereas the concentrated cell slurry (now containing the protein-rich microbes) strikes to the ultimate drying stage.

A drum dryer, heated with low-pressure steam, removes the remaining water from the product. The ultimate result’s Solein®: a flour-like powder that’s 78% protein, prepared for incorporation into meals merchandise.[1]

All the facility requires common cleansing utilizing a cleaning-in-place (CIP) system about 4 occasions per 12 months, involving sodium hydroxide and nitric acid options to take care of sterility and meals security requirements.

With the ultimate step full, we are able to now take a look at the ensuing dietary profile:

Dietary Profile: A Protein That Rivals Whey

When Photo voltaic Meals claims Solein® delivers “unmatched worth”, the dietary information backs up that daring assertion. At 78% protein by dry weight, Solein® doesn’t simply compete with conventional protein sources, it typically surpasses them in key metrics that matter most to critical athletes and health-conscious customers.

The whole amino acid profile units Solein® aside instantly. With 43% important amino acids — matching whey protein precisely — Solein® offers all 9 amino acids the human physique can’t synthesize by itself. Much more spectacular is the 20% branched-chain amino acid (BCAA) content material, placing it in elite firm alongside whey (24%) whereas considerably outperforming plant-based options like pea protein (17%) or rice protein (15%).

Solein®’s Full Macronutrient Breakdown:

- 78% protein with all important amino acids

- 10% dietary fiber (40% of that are useful beta-glucans)

- 6% unsaturated fat (primarily heart-healthy oleic acid)

- 2% carbohydrates

- 4% minerals and nutritional vitamins

Solein® combines the very best dietary facets of each animal and plant proteins whereas eliminating their respective drawbacks. You get whey-level amino acid completeness with out the ldl cholesterol or saturated fat! You get plant-level fiber content material with out the anti-nutritional elements or digestive points that plague many plant proteins.

Micronutrient Powerhouse: Notice the Iron, B12, and Calcium Ranges

Solein®’s micronutrient profile reads like a fastidiously designed complement stack. The iron content material hits 110mg per 100g, making it naturally excessive on this essential mineral that girls typically wrestle to get sufficient quantities of. Evaluate this to whey protein’s 0.3mg, and the distinction turns into stark.

The vitamin B12 content material at 5 micrograms per 100g is one other important benefit, particularly for people following plant-based diets or anybody involved about B12 deficiency. Most plant proteins include zero B12, requiring separate supplementation, whereas Solein® delivers significant quantities naturally.

Further minerals embrace 110mg calcium per 100g, matching soy protein and offering important help for bone well being. The whole mineral profile helps not simply protein synthesis however general metabolic operate.

The PDCAAS Good Rating

Maybe most significantly, Solein® achieves a theoretical Protein Digestibility-Corrected Amino Acid Rating (PDCAAS) of 1.0, which is the very best potential protein high quality evaluation ranking. This places it in the identical elite class as whey protein and complete eggs, that means the physique can successfully make the most of practically the entire amino acids Solein® offers.

This “good” PDCAAS rating turns into much more spectacular when you think about that almost all plant proteins fall quick: pea protein scores 0.82-0.93, rice protein manages solely 0.47-0.60, and even soy protein usually ranges from 0.9-1.0. Solein® delivers animal-protein-level utilization with none of the environmental or moral issues.

Practical Fiber Content material

The 10% dietary fiber content material, with 40% of that being beta-glucans, provides important useful worth past primary protein supply. Beta-glucans are well-researched for his or her cholesterol-lowering results and immune system help, usually present in oats and sure mushrooms however uncommon in protein powders.

This fiber content material helps with satiety, digestive well being, and blood sugar administration, turning Solein® into extra than only a protein supply. It turns into a useful meals ingredient that may enhance the general dietary profile of any product it’s added to.

Style Profile: The Taste Benefit

Whereas diet issues, style typically determines real-world adoption. Solein® delivers what Photo voltaic Meals describes as a “creamy mouthfeel with slight nutty taste”. This can be a profile that permits it to “vanish into meals” with out the off-notes that plague many plant proteins.

This makes for a significant benefit over options like pea protein (earthy with bitterness and gritty texture) or soy protein (beany with chalky aftertones and issues of estrogenicity). The impartial style profile means formulators can obtain excessive protein content material with out compromising taste, whereas customers get efficient diet with out the sensory compromises usually required with sustainable protein sources.

The result’s a protein supply that doesn’t ask customers to decide on between diet high quality, sustainability, and performance – it delivers on all three fronts concurrently.

The Environmental Revolution: Solein® vs. Conventional Proteins

The numbers don’t lie, and in terms of environmental affect, Solein® doesn’t simply compete with conventional protein sources… it utterly redefines what’s potential.

Life Cycle Evaluation Knowledge

Based mostly on the great 2021 examine by Järviö et al, the environmental benefits of Solein® grow to be instantly obvious when examined by way of an life cycle evaluation.[1] This peer-reviewed evaluation offers the primary empirical information on Solein®’s environmental footprint, transferring past theoretical projections to real-world measurements from Photo voltaic Meals’ manufacturing facility.

-

Land use

The land effectivity positive factors are unbelievable: Solein® requires 95% much less land than animal proteins whereas attaining 20 occasions extra effectivity than plant-based options.[1] To place this in perspective, producing one kilogram of Solein® protein requires just about no agricultural land, whereas beef cattle demand intensive grazing areas and feed crop cultivation spanning hundreds of sq. meters.

-

Water consumption

Conventional protein manufacturing is notoriously water-intensive, with beef requiring roughly 15,000 liters per kilogram of protein. Solein®’s water necessities are dramatically decrease, using solely the water wanted for electrolysis and primary processing and cleansing operations. The closed-loop system recycles water all through the manufacturing course of, eliminating the large freshwater calls for that plague typical agriculture.

-

Carbon effectivity

When powered by Finland’s ample renewable electrical energy, Solein® demonstrates wonderful manufacturing effectivity with considerably decrease CO2 emissions than conventional protein sources.[1] The managed manufacturing atmosphere achieves outstanding effectivity: Solein® generates simply 1.57 kg CO2-equivalent per kilogram of protein when utilizing renewable power, in comparison with beef manufacturing estimated at 204.33 kg and dairy manufacturing at 172.87 kg CO2-equivalent per kilogram of protein.

This effectivity benefit stems from the streamlined manufacturing course of that eliminates the intensive provide chains, transportation, and processing steps required for conventional protein sources.

-

Power issues

Whereas Solein® requires important electrical energy enter (18-25 kWh per kilogram of biomass), this power demand turns into environmentally impartial when sourced from renewable sources,[5] of which Finland has ample quantities. Additional, this electrical energy replaces the large, distributed power prices embedded in conventional agriculture, from gasoline for tractors and transport to fertilizer manufacturing and livestock feed processing and storage.

Sustainability Metrics

Photo voltaic Meals isn’t performed but:

-

Useful resource Independence

Maybe probably the most revolutionary side of Solein® manufacturing is its full independence from agricultural programs. Not like each different protein supply presently accessible, Solein® requires no agricultural land, climate cooperation, or particular local weather situations. Manufacturing facility 01 operates repeatedly no matter seasons, droughts, floods, or temperature extremes that routinely disrupt world meals manufacturing.

This independence extends past climate resilience. Solein® manufacturing doesn’t compete with meals crops for fertile land, doesn’t require particular soil situations, and doesn’t rely upon agricultural chemical compounds or pesticides. The expertise basically disconnects protein manufacturing from the environmental variables that make conventional agriculture more and more susceptible to local weather change.

-

Scalability and Location Independence

The situation-agnostic nature of Solein® manufacturing opens up unprecedented prospects. The expertise may be deployed in deserts, Arctic areas, and even outer area – wherever electrical energy and primary infrastructure may be established.[6] Photo voltaic Meals has already demonstrated this potential by being the worldwide winner of NASA’s Deep House Meals Problem, creating ideas for astronaut diet throughout Mars missions.

This scalability isn’t theoretical. Desert installations may leverage ample photo voltaic power for renewable electrical energy whereas avoiding competitors for arable land. Arctic deployments may present native protein manufacturing in food-insecure areas. City installations may carry protein manufacturing on to inhabitants facilities, eliminating transportation-related emissions.

We’ll be protecting the purposes for outer area in better element afterward.

-

Power Effectivity Over Photosynthesis

The organic equipment powering Solein® achieves effectivity ranges that make photosynthesis look primitive by comparability. Hydrogen-oxidizing micro organism show 20 occasions greater effectivity than pure photosynthesis and roughly 200 occasions extra effectivity than meat manufacturing.[6]

This effectivity benefit stems from the elimination of organic inefficiencies inherent in conventional meals manufacturing. Crops should dedicate important power to structural parts like cellulose that people can’t digest. Animals require large feed inputs to take care of primary metabolic capabilities earlier than producing edible protein. Solein®’s microbes, against this, channel practically all their power instantly into protein synthesis, attaining conversion efficiencies that method theoretical maximums.

The environmental revolution pioneered by Photo voltaic Meals extends past easy effectivity positive factors. It basically decouples protein manufacturing from the planetary useful resource constraints that threaten world meals safety. Whereas conventional agriculture more and more competes for land, water, and local weather stability, Solein® presents a pathway to ample protein that truly reduces strain on these crucial sources.

Regulatory Standing and Security Profile

The trail from laboratory innovation to shopper plates (or shaker cups) requires navigating quite a few advanced regulatory frameworks designed to make sure meals security. Photo voltaic Meals has systematically approached this problem, securing approvals in key markets whereas constructing complete security documentation that positions Solein® for world acceptance.

Present Approvals

As of June 2025, the next has been established:

-

United States (2024)

Photo voltaic Meals achieved a major milestone in September 2024 by acquiring self-affirmed GRAS (Usually Acknowledged As Protected) standing for Solein® in the US. This designation permits Photo voltaic Meals to market Solein® as a meals ingredient with out requiring pre-market approval from the FDA, offered they’ll show that certified consultants typically acknowledge the ingredient as secure beneath the situations of its supposed use.

This self-affirmed standing displays Photo voltaic Meals’ confidence of their complete security database and the ingredient’s established security profile based mostly on intensive testing and analysis by an unbiased panel of established scientists.

-

Singapore (2022)

Solein® made historical past by receiving its first novel meals regulatory approval in 2022 from the Singapore Meals Company (SFA), marking the primary time any protein produced completely from air and electrical energy gained industrial meals approval wherever on this planet. This groundbreaking approval permits for the import, manufacture, and sale of meals merchandise containing Solein® all through Singapore.

Singapore’s approval wasn’t only a regulatory checkbox: It represented a watershed second for mobile agriculture and various proteins. As Photo voltaic Meals CEO Pasi Vainikka famous, “I’d examine this to the invention of the potato: we’re introducing a wholly new ingredient to the world of meals.” The SFA’s rigorous novel meals evaluation course of included complete analysis of manufacturing strategies, dietary composition, security information, and supposed makes use of.

-

Pending markets

Photo voltaic Meals has strategically filed novel meals dossiers within the European Union and United Kingdom, with EU approval estimated for 2026. These submissions signify the following part of worldwide market entry, focusing on areas with subtle regulatory frameworks and powerful demand for sustainable protein options.

The EU novel meals regulation requires complete security documentation just like Singapore’s rigorous evaluation, together with detailed manufacturing course of descriptions, compositional evaluation, dietary evaluation, toxicological research, and allergenicity analysis. Nonetheless, the EU’s extra advanced bureaucratic processes usually prolong approval timelines considerably past different jurisdictions. Photo voltaic Meals’ proactive method in these markets demonstrates their dedication to navigating various regulatory pathways whereas sustaining constant security requirements.

High quality management

The managed atmosphere in Photo voltaic Meals’ Manufacturing facility 01 permits steady monitoring and sterile situations all through the manufacturing course of. Not like agricultural programs uncovered to soil pathogens, erratic climate, animal waste, pests, numerous endocrine-disrupting pesticides, and different contamination dangers, Manufacturing facility 01 operates as a closed system with complete high quality assurance.

The power additionally incorporates cleaning-in-place (CIP) programs requiring 120°C warmth to take care of sterility. Pasteurization happens at a lot decrease temperatures to make sure meals security whereas preserving dietary integrity.[1] Temperature, pH, and gasoline concentrations bear real-time monitoring with automated changes to take care of optimum manufacturing situations.

This degree of course of management permits constant protein high quality and composition – one thing practically unattainable to realize with agricultural programs topic to differences due to the season, climate fluctuations, and organic variability. Manufacturing facility 01 offers manufacturing-level precision utilized to organic protein manufacturing, setting new requirements for reliability and consistency in meals manufacturing.

Security Concerns

The regulatory successes point out how critical Photo voltaic Meals is relating to security and toxicity issues:

-

Toxicity Research

Photo voltaic Meals has accomplished complete security assessments that meet worldwide requirements for novel meals components. These research embody acute toxicity testing, sub-chronic feeding trials, and genotoxicity screening — the gold customary battery of assessments required for regulatory approval of latest meals components.

The protection analysis course of included each in vitro and in vivo research designed to determine any potential adversarial results from Solein® consumption. Outcomes constantly demonstrated no toxicological issues at supposed use ranges, supporting the ingredient’s security profile for human consumption. This intensive toxicological database offered the inspiration for regulatory submissions throughout a number of jurisdictions.

-

Allergen profile (or Lack Thereof)

Considered one of Solein®’s important security benefits is the absence of frequent meals allergens. Not like many conventional protein sources, Solein® accommodates no dairy, eggs, peanuts, tree nuts, soy, wheat, fish, or shellfish – the eight main allergens chargeable for the overwhelming majority of meals allergic reactions.

This profile represents a significant benefit for meals producers searching for to create inclusive merchandise that don’t require allergen labeling or cross-contamination issues. The protein’s microbial origin eliminates the advanced allergenic proteins present in agricultural crops and animal merchandise, making it appropriate for people with a number of meals sensitivities.

-

Shelf Life / Stability

Photo voltaic Meals has reported that Solein® has a shelf-life of 24 months (two years), placing it on par with different protein sources.

The mixture of rigorous regulatory approvals, complete security testing, composition with no main allergens, and sterile manufacturing strategies positions Solein® as one of the crucial thoroughly-vetted and managed protein components coming into the market. As regulatory frameworks evolve to accommodate mobile agriculture improvements, Photo voltaic Meals’ proactive security method establishes the usual for next-generation protein components.

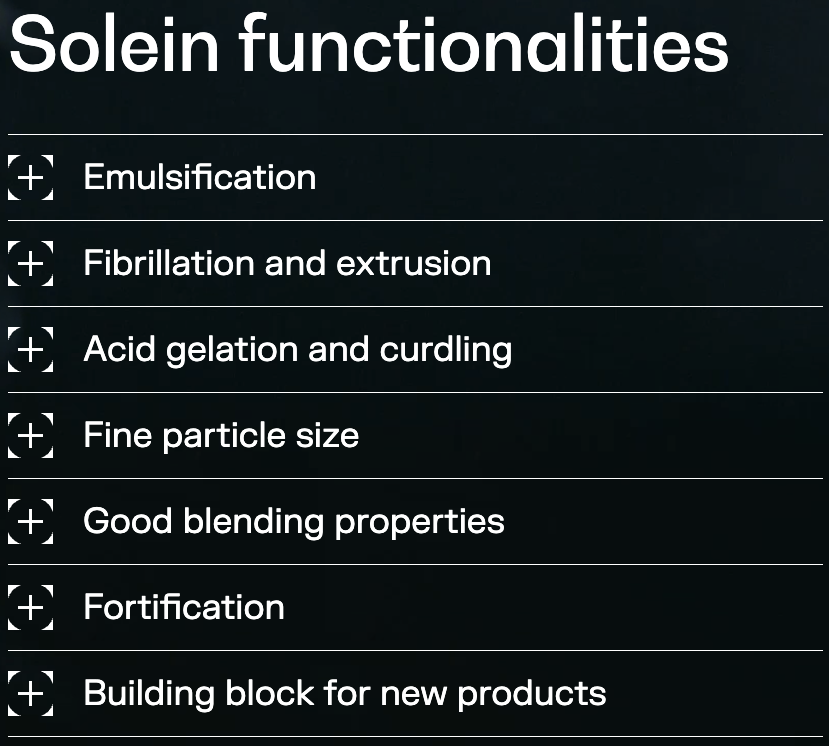

Purposes and Practical Properties

Whereas Solein®’s revolutionary manufacturing technique captures headlines, its real-world worth lies in seamless integration throughout meals classes. Photo voltaic Meals has developed what they describe as an “all-purpose protein” that adapts to just about any software whereas delivering superior performance in comparison with conventional options.

Meals Business Integration

- Impartial style: Maybe Solein®’s most commercially worthwhile attribute is its potential to “vanish into meals” with out altering acquainted taste profiles. Solein® delivers what Photo voltaic Meals describes as a “delicately distinctive taste with a pleasing word of umami.” The protein enhances present flavors quite than masking them, permitting meals producers to realize excessive protein content material with out the sensory compromises usually required with sustainable options.

This taste neutrality turns into a major aggressive benefit when formulating shopper merchandise. The place pea protein would possibly require further masking brokers or taste programs and has a nagging gritty texture, Solein® integrates cleanly, lowering formulation complexity and ingredient prices whereas sustaining clear label attraction.

- Practical versatility: Photo voltaic Meals has efficiently demonstrated Solein® throughout 5 main meals classes, every requiring totally different useful properties. In various dairy purposes like ice cream, yogurts, and cheese options, Solein® offers the protein construction and creamy mouthfeel that buyers anticipate. The protein’s pure umami traits improve the wealthy, satisfying style profile that plant-based dairy merchandise typically wrestle to realize.

- For meat options, Solein® presents full amino acid profiles that match animal proteins whereas offering the useful binding and texture-building properties important for real looking meat analogues. The protein’s wonderful powder type permits easy integration into floor meat purposes, sausages, and shaped merchandise.

- In pasta and baked items, Solein® capabilities as each a protein fortification ingredient and an egg substitute system. The protein’s binding properties help dough construction whereas its impartial colour maintains the visible attraction of conventional wheat-based merchandise.

- Beverage purposes profit from Solein®’s wonderful solubility and clear style, enabling high-protein drinks with out the chalky mouthfeel frequent with plant proteins.

- Culinary specialties together with soups, dressings, seasonings, and sauces could transform probably the most demanding software space, the place any off-flavor turns into magnified and customers are growingly uninterested in extreme industrially-processed seed oils. Solein®’s potential to boost quite than compete with advanced taste programs makes it supreme for premium culinary purposes.

- Processing stability: Not like many different proteins that denature or lose performance throughout processing, Solein® maintains its integrity by way of numerous manufacturing processes. The protein withstands the thermal processing required for shelf-stable merchandise, the pH variations in fermented meals, and the mechanical stresses of extrusion and forming operations. This processing stability reduces manufacturing complexity and ensures constant end-product high quality.

Ideas in Partnership with Sensapure Flavors

Photo voltaic Meals has partnered with Sensapure Flavors, the {industry}’s top-tier taste home, to develop optimized taste programs that showcase Solein®’s versatility throughout purposes. This collaboration permits manufacturers and producers to expertise correctly formulated Solein® merchandise at tradeshows and growth conferences, accelerating industrial adoption by demonstrating the ingredient’s true potential when expertly formulated. They’re accessible for manufacturers and at tradeshows from both firm.

Complement Business Potential

As a protein supply (delivering 43% important amino acid content material and 20% BCAA content material), Solein® offers the leucine, isoleucine, and valine essential for muscle protein synthesis that the sports activities and lively diet {industry} calls for. Its clear label attraction appeals to an {industry} more and more targeted on transparency and sustainability, with a single ingredient: Solein®. The sustainability angle turns into more and more necessary as complement customers — particularly in vegan/vegetarian demographics — search merchandise that align with their values.

From a technical standpoint, Solein® presents a number of benefits for complement formulators. The wonderful powder type ensures easy mixing and wonderful dispersibility, eliminating the grittiness that plagues many plant proteins. The impartial style profile permits for inventive taste growth with out the masking challenges related to pea or hemp proteins.

The pure iron content material at 110mg per 100g and vitamin B12 at 5 micrograms per 100g add useful diet advantages for girls and plant-based dieters that get rid of the necessity for separate mineral and vitamin fortification.

Excessive Purposes: House and Past

Maybe probably the most wild demonstration of Solein®’s versatility comes from its choice as a NASA Deep House Meals Problem winner in 2024. The competitors sought improvements able to feeding astronauts throughout three-year Mars missions, the place resupply is unattainable and each gram of weight issues.

Photo voltaic Meals’ area software idea envisions a 40-liter bioreactor offering day by day protein content material for six astronauts throughout long-term area missions. The closed-loop system not solely produces protein however releases oxygen as a byproduct, contributing to life help programs. This excessive software validates Solein®’s potential for deployment within the harshest environments conceivable. In any case, if it really works in area, it could actually work wherever on Earth.

Solein®: The Way forward for Protein is Right here

We stand at a pivotal second within the historical past of not simply protein, however meals manufacturing altogether. Whereas the complement {industry} has spent a long time optimizing extraction strategies, enhancing flavors, and perfecting amino acid profiles inside present protein sources, Solein® brings one thing basically totally different: a full reimagining of how protein will get made.

Key Factors to Take Away:

- Solein® represents a basic shift in protein manufacturing methodology. This isn’t one other plant protein and even one other fermentation course of — it’s the first protein supply utterly disconnected from agriculture. Manufacturing facility 01 proves that high-quality, protein may be produced from components derived from air and renewable electrical energy, scaling manufacturing strategies that surpass pure photosynthesis by orders of magnitude.

- Environmental advantages are substantial and scientifically validated. The peer-reviewed analysis from Järviö et al. demonstrates environmental impacts that aren’t simply decrease than conventional proteins… they’re in a unique class completely. With 95% much less land use than animal proteins and 20 occasions greater effectivity than plant options, Solein® presents the primary actually sustainable protein supply that may scale to fulfill world demand with out competing for planetary sources.

- Industrial viability is already right here with Manufacturing facility 01. Not like many different proteins that stay in pilot phases or wrestle with cost-effectiveness, Solein® is already in industrial manufacturing. The 70-hour manufacturing cycle and steady operation show this expertise works at industrial scale proper now, not in some theoretical future.

- Regulatory acceptance is rising globally. With GRAS standing obtained in the US and novel meals approval in Singapore, Solein® has cleared the regulatory hurdles that usually delay or stop various protein adoption. The excellent security testing, no main allergens, and sterile manufacturing course of place Solein® for regulatory approval in further markets.

- Future implications prolong far past simply one other protein powder. As Photo voltaic Meals co-founder Pasi Vainikka famous, “I’d examine this to the invention of the potato: we’re introducing a wholly new ingredient to the world of meals.” Solein® opens prospects for protein manufacturing in deserts, city facilities, Arctic areas, and even area installations. It represents the start of location-independent, weather-independent, agriculture-independent protein manufacturing.

There’s a Larger Story Right here

The broader implications reshape how we take into consideration meals safety, environmental sustainability, and world protein provide chains. If protein may be produced wherever electrical energy and primary infrastructure exist, the geopolitical implications alone are staggering. Protein-importing nations may obtain meals safety independence. City facilities may produce their very own protein provides. Distant areas may entry high-quality diet with out advanced provide chains.

For the complement {industry} particularly, with Solein®, Photo voltaic Meals has pioneered the primary protein supply that eliminates conventional trade-offs. Manufacturers and formulators now not want to decide on between sustainability and efficiency, between clear label and full amino acids, between environmental accountability and superior style. Solein® delivers on all fronts concurrently.

The Future Has Formally Arrived

The protein revolution is going on now, not in some distant future. Manufacturing facility 01 is producing Solein® right this moment. Regulatory approvals are increasing. Industrial partnerships are forming. The query isn’t whether or not protein “out of skinny air” will remodel the {industry} — it’s how rapidly manufacturers and customers will embrace this paradigm shift.

Comply with PricePlow to remain knowledgeable about Solein®’s market entry and take into account its potential function in sustainable diet. For complement manufacturers, it is a new alternative to distinguish with genuinely superior sustainability credentials whereas sustaining or enhancing product efficiency. For customers, it presents a pathway to help dairy-free, non-GMO, vegan-friendly diet with out compromising on effectiveness.

The age of meals “out of skinny air” has formally begun. The one query is whether or not you’ll be among the many early adopters who acknowledge this transformation or look ahead to the remainder of the {industry} to catch up.

Discussion about this post